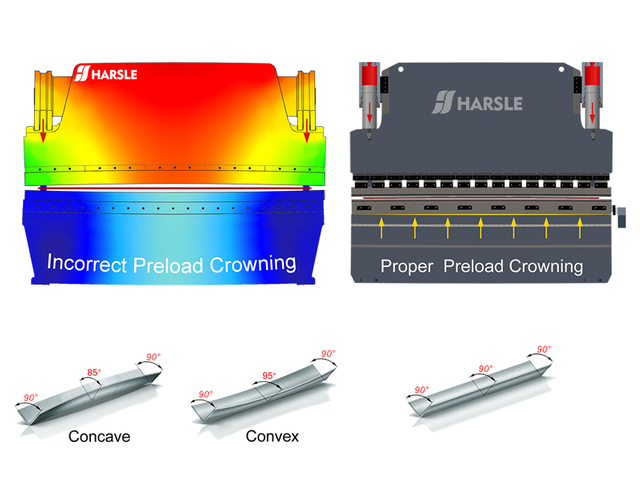

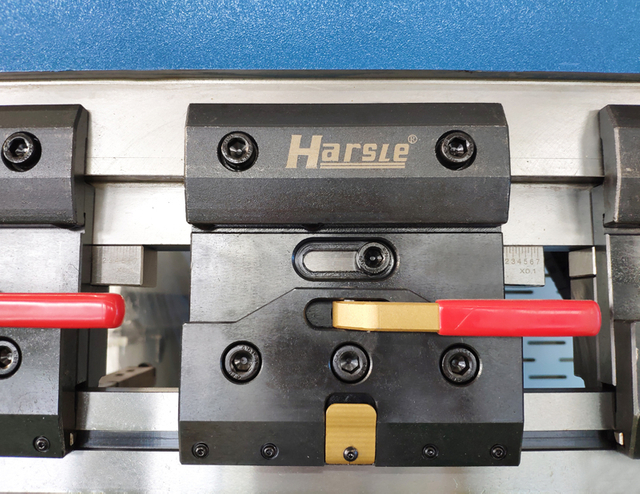

The crowning system on the HARSLE press brake enables to offset the possible deformations automatically while bending. And the bending angle is constant along the entire workpiece.

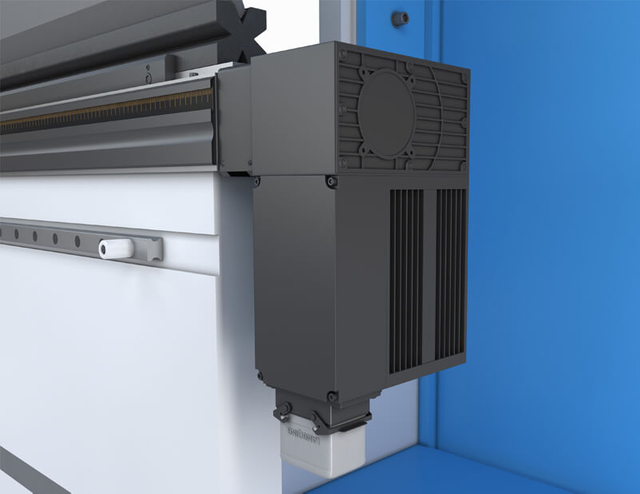

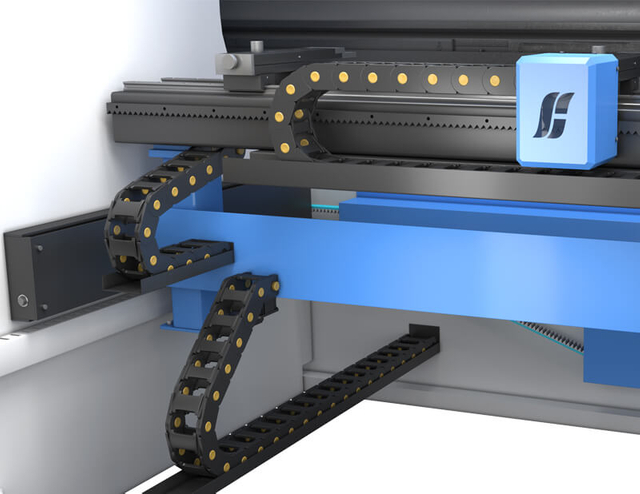

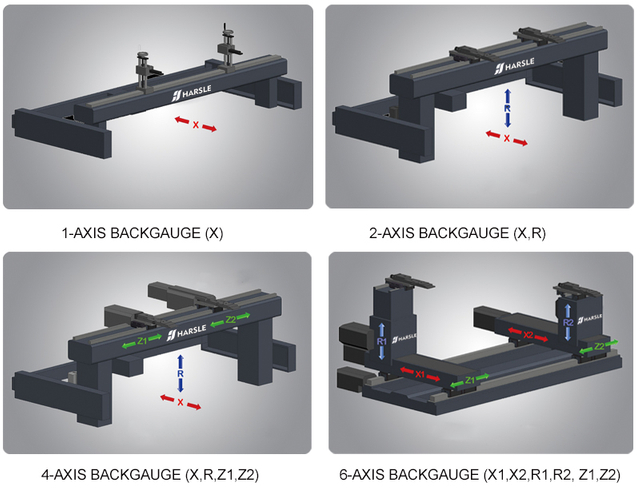

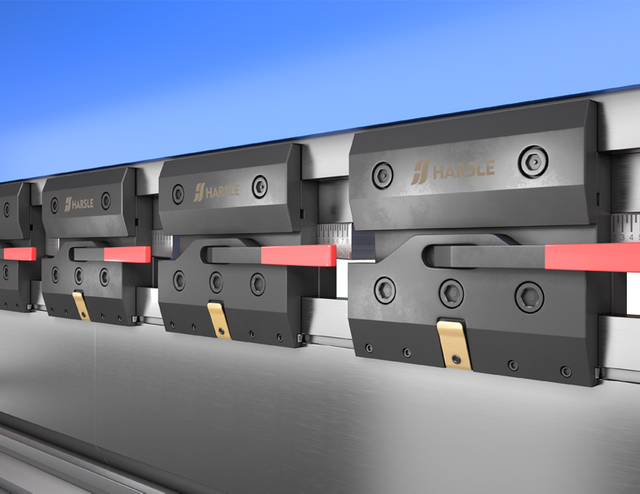

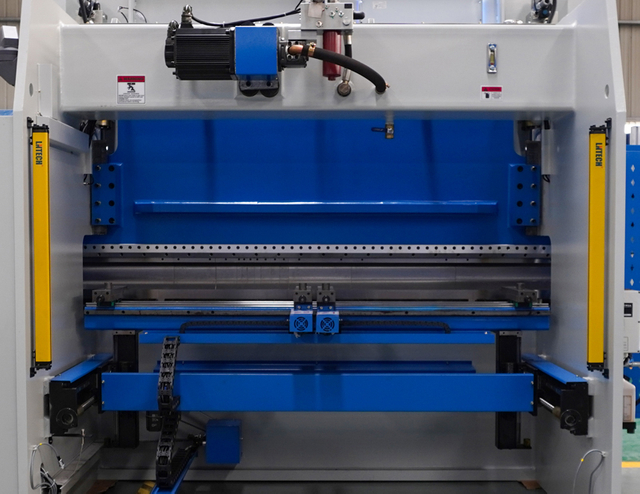

The backgauge is driven by digital AC servo motors, precision ball screw and linear guide, all from the first-brand line. The bending accuracy is guaranteed by the electro-hydraulic servo system, full closed-loop control synchronization and hydraulic crowning system. The overall frame is welded with steel plate, tempered and vibrated again to eliminate stress, and sprayed with anti-rust paint after spraying the surface of the frame.

English

English Pусский

Pусский