Adjusting the slider leveling of a hydraulic press typically involves the following steps:

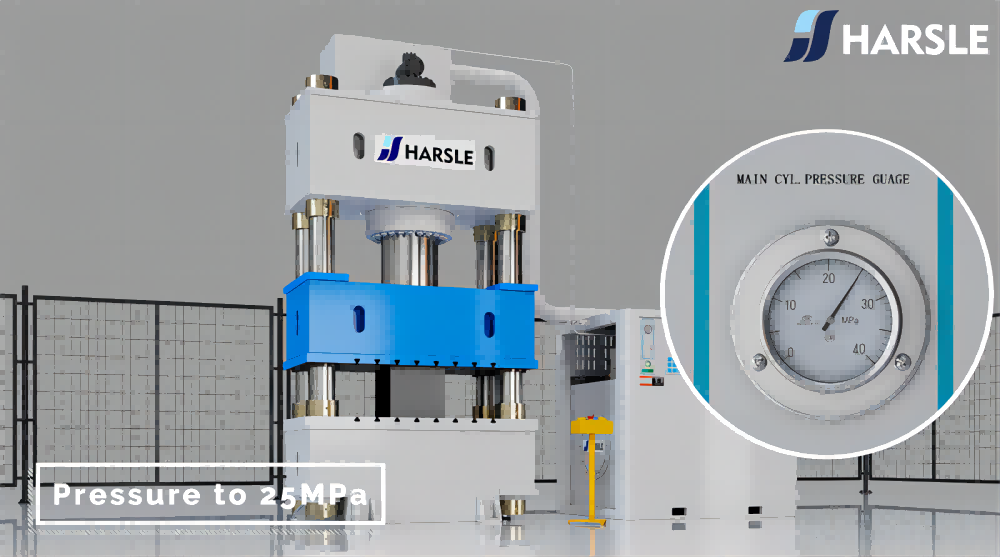

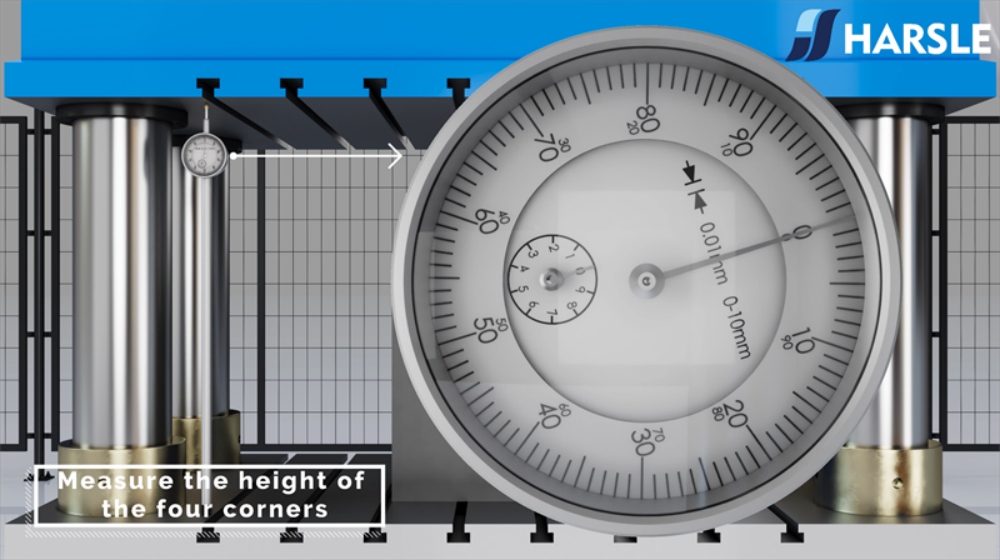

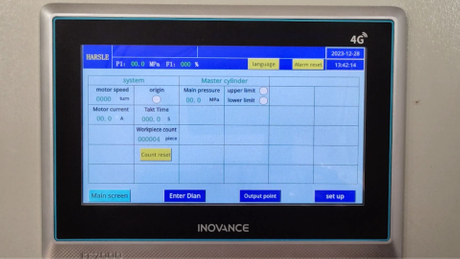

Check Current Leveling: Place a pad on the table, adjust the system pressure to 25MPa, and pressurize.

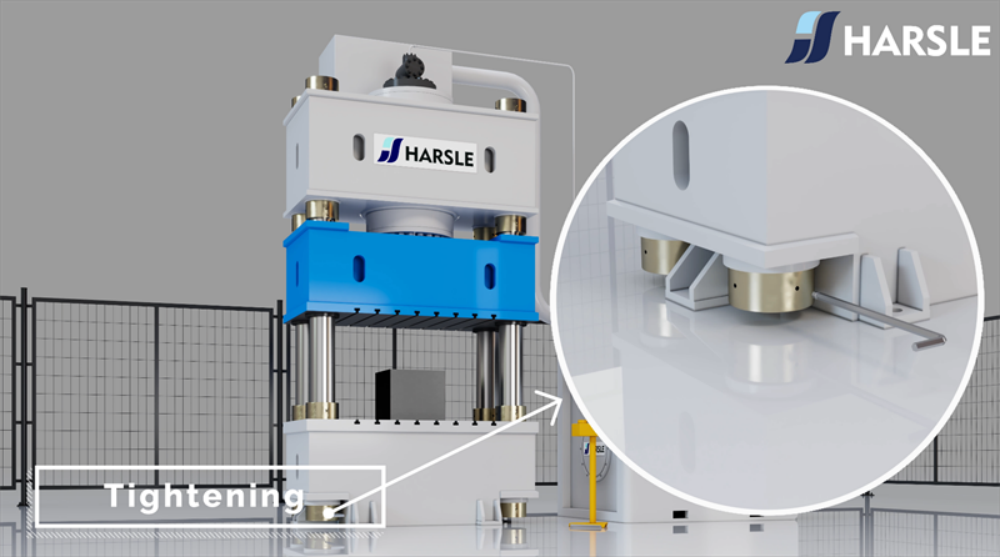

Tighten all screws shown.

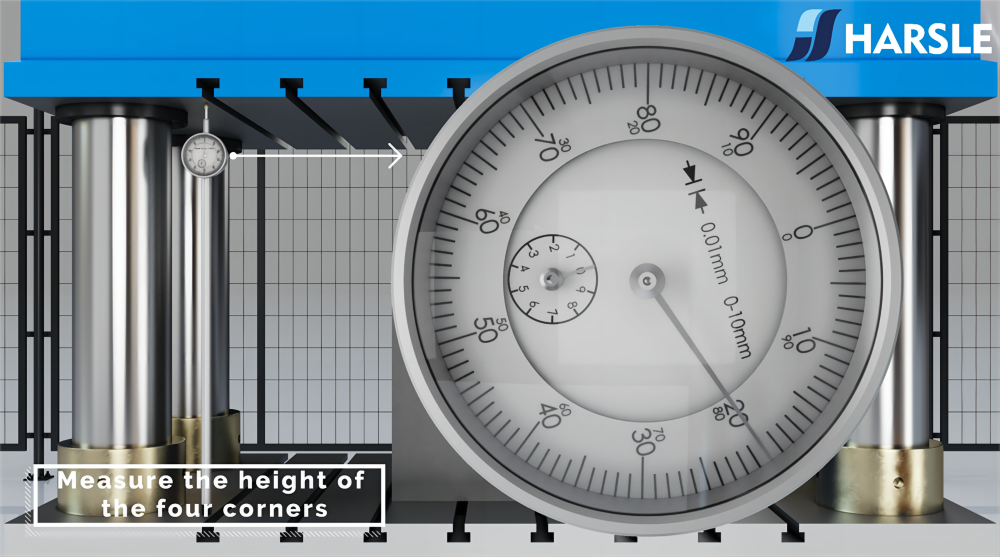

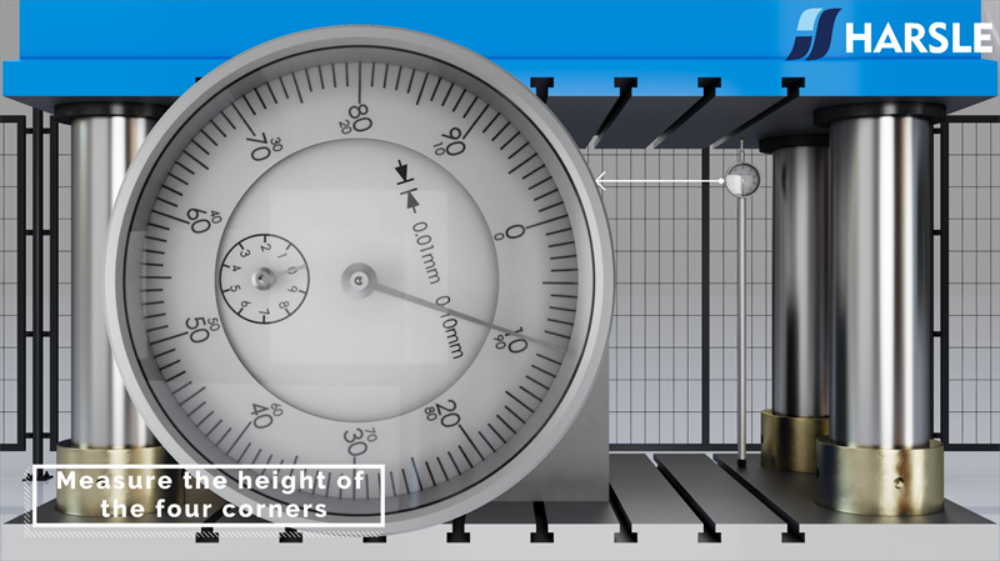

Then test the level of the corners of the slider without pressure with a leveling tool, such as a spirit level, to check the current orientation of the slider. This will help you identify whether it needs adjustment.

As shown in the animation, there is a difference of 2mm on the left front and 1mm on the right rear.

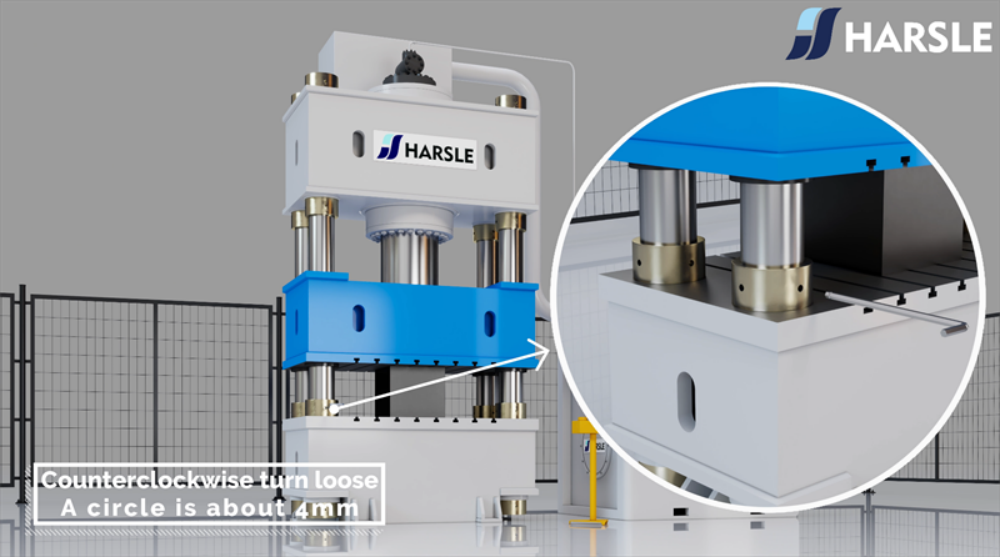

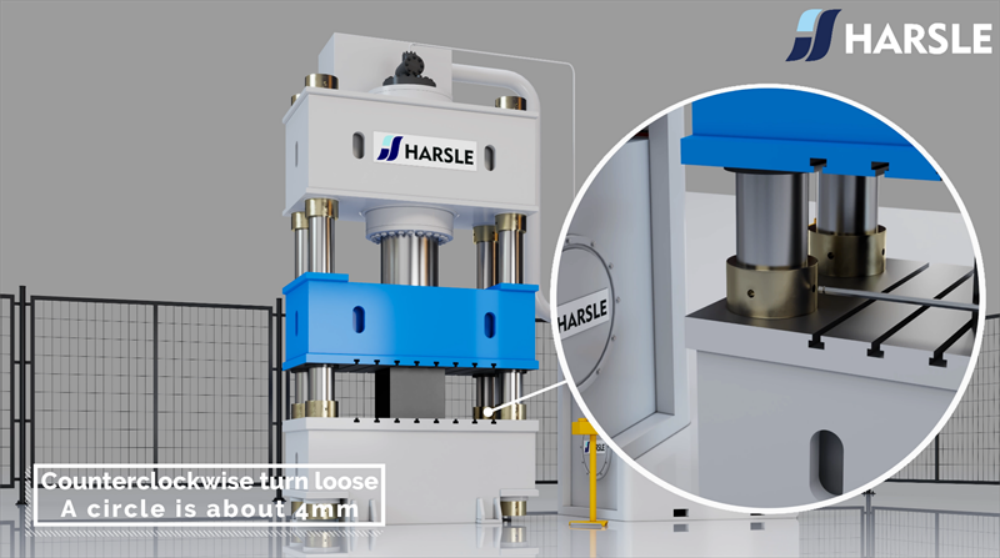

Adjustment Bolts: Loosen the bolts on the workbench on the left front and right rear side to allow for adjustment. Counterclockwise turn loose and a full circle is about 4mm.

Based on the previous errors, we loosened the nuts at the corresponding positions by 90 degrees and 45 degrees, i.e., adjusted them by 2mm and 1mm, respectively.

Use the leveling tool to adjust the slider to the desired orientation. This typically involves raising or lowering one side of the slider until it is level. Make small adjustments and frequently check the level to ensure accuracy.

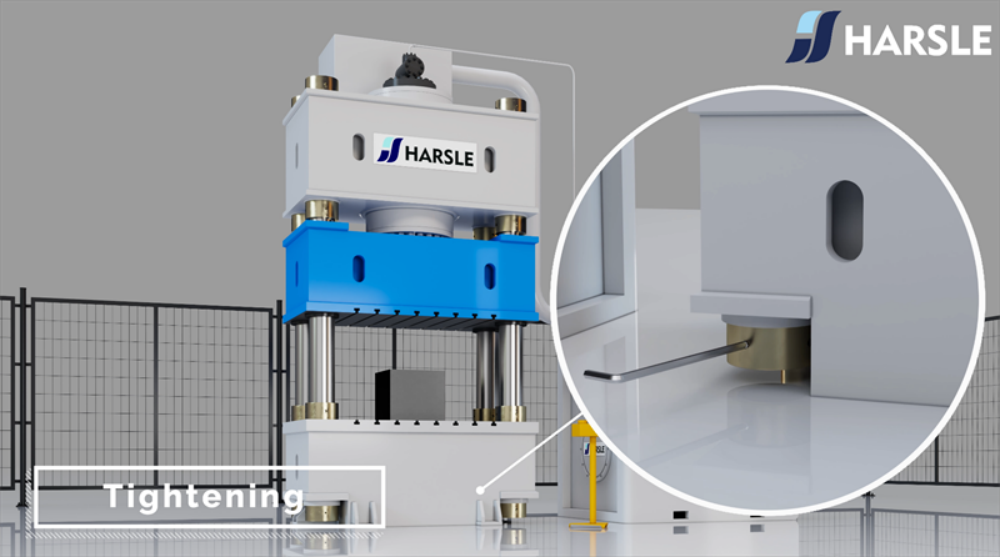

Tighten Bolts: With no pressure, tighten the left front and right rear screws under the workbench.

Then re-pressurize to 25MPa and tighten the screws on the workbench. Use a torque wrench if necessary to ensure proper tightening.

Final Check: Recheck the leveling of the slider to ensure it has remained stable after testing. Make any additional adjustments if necessary.

Test Operation: Test the hydraulic press to ensure it operates smoothly and efficiently. Check for any unusual noises or vibrations that may indicate further adjustments are needed.

Safety Checks: Before resuming regular operation, perform a final safety check to ensure all guards and safety features are in place and functioning properly.

English

English Pусский

Pусский